Zhengzhou ChangHeYue New Material CO.,LTd

Why MSDS Matters for Graphitized Petroleum Coke (GPC)

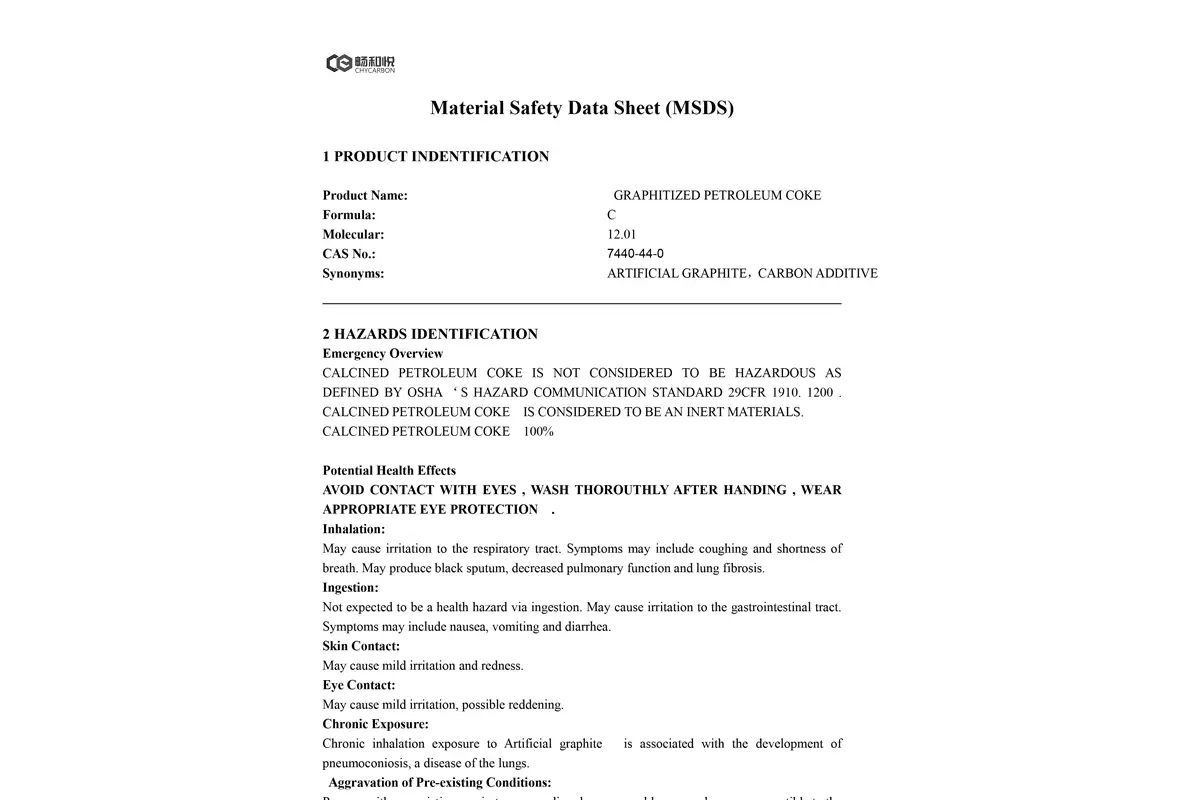

Material Safety Data Sheets (MSDS/SDS) are critical for global procurement of graphitized petroleum coke (GPC), a premium carbon additive used in steelmaking and foundries. As a non-hazardous industrial material, GPC’s MSDS provides compliance documentation for REACH, OSHA, and international shipping regulations.

Key Safety Attributes in GPC MSDS

Based on industrial production standards:

- Chemical Composition

- Fixed carbon: ≥98.5%

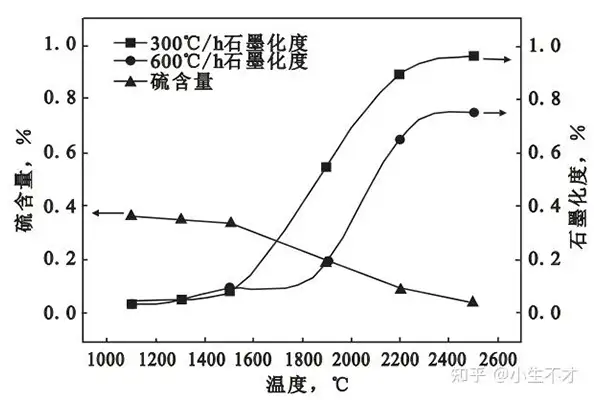

- Sulfur content: ≤0.05% (ultra-low due to 2500-3000°C graphitization)

- Nitrogen: ≤300 ppm

- Moisture: ≤0.5% (optimized for metallurgical efficiency)

- Physical Properties

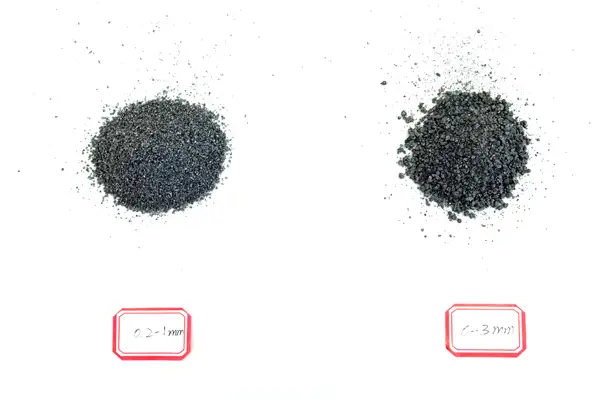

- Appearance: Black granular solid with metallic luster

- Density: 1.5-1.8 g/cm³ (enhanced absorption in molten metal)

- Particle sizes: 0.2-10mm (customizable for EAF/LD converter needs)

- Handling & Storage

- Dust control: Recommend NIOSH-approved N95 respirators during bulk handling

- Fire safety: Non-flammable under standard conditions (auto-ignition >400°C)

- Spill management: Use dry sweeping methods; avoid water to prevent dust dispersion

MSDS-Driven Value in GPC Supply Chains

- Customs Clearance

- HS code alignment: 3801.10 (carbonaceous pastes/electrodes)

- IMDG certification: UN No. not required for properly graphitized grades

- Sustainability Compliance

- RoHS/REACH: No SVHC (Substances of Very High Concern) identified

- Carbon footprint: 0.12 tCO2e/ton GPC (verified by ISO 14064-3)

- Technical Advantages

- Reduces slag formation in steelmaking (vs. non-graphitized carburizers)

- 92-96% carbon absorption rate (validated in 50T+ EAF trials)

Accessing GPC MSDS Documentation

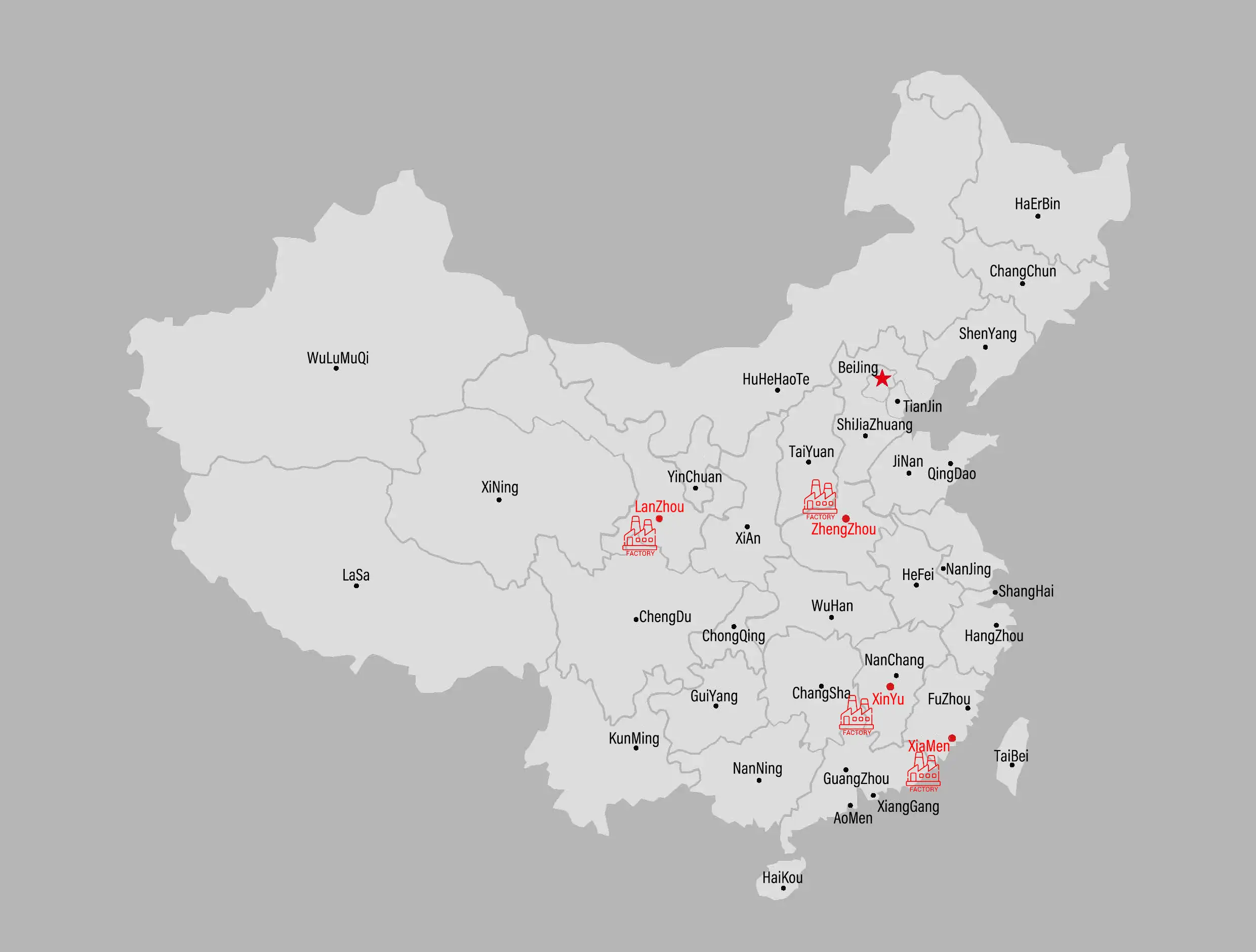

As a vertically integrated GPC manufacturer with facilities in Jiangxi, Gansu, Henan, and Fujian, we provide:

- Multilingual MSDS: English/ESD/Chinese versions for global clients

- Batch-specific reports: Traceable to production dates and furnace IDs

- On-demand updates: Compliant with 2025 GHS Revision 8 standards