Zhengzhou ChangHeYue New Material CO.,LTd

Carburizers play a pivotal role in the production of ductile iron, enhancing both quality and efficiency through various mechanisms. Here’s a detailed analysis based on industry practices and research:

1. Precision Adjustment of Carbon Content

Ductile iron requires strict control of carbon levels, which can be challenging when using low-carbon scrap steel. By adding high-quality carburizers (e.g., graphitized petroleum coke or synthetic graphite), manufacturers can increase carbon content while reducing reliance on expensive pig iron. For instance, a foundry successfully boosted scrap steel usage by 30% while maintaining quality stability, significantly cutting costs and enhancing competitiveness.

2. Optimizing Graphite Morphology

The distribution of graphite nodules directly impacts mechanical properties. Traditional pig iron often produces coarse graphite, weakening strength. Graphitized carburizers, however, promote the formation of fine, uniform graphite spheres. A case study showed that using graphitized petroleum coke improved graphite distribution from “uneven” to “fine and uniform,” enhancing both strength and toughness.

3. Cost Reduction and Process Efficiency

Carburizers substitute high-cost pig iron with cheaper scrap, reducing material expenses. A steel enterprise adjusted carbon levels in high-carbon steel using premium carburizers, meeting quality standards and gaining market share. Additionally, they shorten melting times and lower energy consumption, optimizing production workflows.

4. Enhancing Machinability and Service Life

By improving graphite distribution and reducing impurities, carburizers increase切削性 (machinability), reducing processing resistance. A machinery manufacturer saw切削效率 (cutting efficiency) rise by 20% and extended component lifespan by 15%. They also minimize defects like porosity and shrinkage, improving surface quality.

5. Selection and Application Guidelines

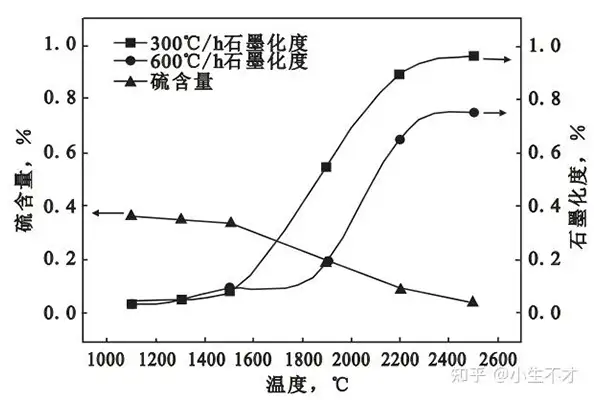

- Prioritize Graphitized Carburizers: Materials like graphitized petroleum coke or synthetic graphite offer high carbon content (≥98.5%) and low sulfur/phosphorus, ensuring stable performance.

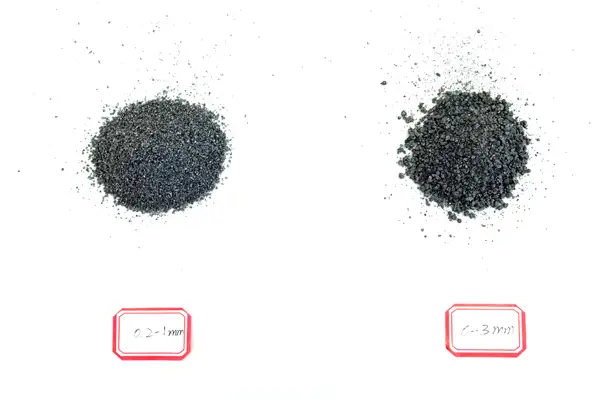

- Control Particle Size and Addition Timing: Fine particles (1-8mm) dissolve faster; add at 1420-1500°C and hold for 2-3 minutes for optimal absorption.

- Tailor to casting Type: Ductile iron benefits most from graphitized carburizers, while gray iron may use calcined coal or metallurgical coke.

Conclusion

Carburizers are indispensable in ductile iron production, balancing quality, cost, and efficiency. As process optimization and new carburizer (novel carburizer) development continue, their role in sustainable manufacturing will expand. Manufacturers must select appropriate types and parameters to maximize benefits.