Zhengzhou ChangHeYue New Material CO.,LTd

Introduction

Carburizers are essential additives in metallurgy to enhance carbon content in steel and cast iron. Among them, fully graphitized and semi-graphitized carburizers dominate the market. This article explores their properties, advantages, and optimal use cases to help you make informed decisions.

1. Fully Graphitized Carburizer

Properties:

- High Crystallinity: Achieves near-perfect graphite structure (≥98% carbon).

- Low Impurities: Sulfur and nitrogen content typically below 0.05%.

- Fast Absorption: High reactivity due to ordered graphite layers, reducing dissolution time in molten metal.

Advantages:

- Superior Performance: Ideal for high-grade steel and ductile iron production, ensuring minimal slag formation.

- Consistency: Uniform carbon distribution improves mechanical properties like tensile strength.

Applications:

- Automotive components (e.g., engine blocks, gears).

- Precision casting requiring low gas porosity.

2. Semi-Graphitized Carburizer

Properties:

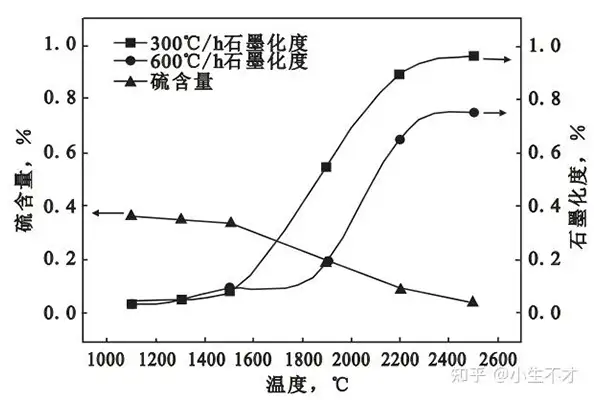

- Partial Crystallinity: Graphitization degree ranges 50–80%.

- Moderate Reactivity: Slower absorption than fully graphitized types but more cost-effective.

Advantages:

- Balanced Cost-Performance: Suitable for mid-range steel alloys and general foundry use.

- Flexibility: Adaptable to varying furnace conditions (e.g., induction furnaces).

Applications:

- Construction steel and machinery parts.

- Gray iron casting where extreme purity isn’t critical.

Key Comparison

| Feature | Fully Graphitized | Semi-Graphitized |

|---|---|---|

| Graphitization | ≥98% | 50–80% |

| Cost | Higher | Lower |

| Absorption Speed | Fast | Moderate |

| Best For | High-grade alloys | General foundry work |

Conclusion

Choose fully graphitized carburizers for premium alloys requiring high purity, and semi-graphitized for cost-sensitive projects. Always verify supplier certifications (e.g., ISO 9001) for quality assurance.