Zhengzhou ChangHeYue New Material CO.,LTd

CHYCARBON Debuts at 2025 Steel Casting and Metallurgical Materials Supply and Demand Summit, Exploring New Opportunities for Industrial Synergy

From March 18 to 19, 2025, the “2025 Steel Casting and Metallurgical Materials Enterprise Supply and Demand Negotiation Summit (Dezhou Station)” was grandly held in Dezhou, Shandong Province. As a emerging enterprise in China’s metallurgical materials sector, Zhengzhou CHYCARBON New Materials Co., Ltd. showcased its core products at the exhibition, engaging with over 200 furnace material enterprises, 20 steel enterprises, and research institutions nationwide to discuss industry trends, deepen supply-demand connectivity, and promote collaborative innovation across the industrial chain.

Focusing on Industrial Upgrading, the Summit Builds an Efficient Cooperation Platform

Themed “Precision Supply and Demand, Innovation-Driven,” the summit aimed to address challenges faced by the steel industry, including capacity adjustments, cost pressures, and technological upgrades. It attracted procurement leaders from leading enterprises such as Qing拓 Group, Shanggang Group, and Jiangsu Changqiang, as well as experts from research institutions like Central South University and Shanggang Research Institute. The event featured five exhibition zones: metallurgical carbon, anode materials, ferroalloys, metallurgical additives, and equipment environmental protection, showcasing cutting-edge products like carburizers, graphite electrodes, and special alloys. In-depth discussions were held on hot topics such as opportunities in the carbon industry, cost control for anode materials, and ultra-clean steel technology.

CHYCARBON: Empowering Industry Development with Technological Innovation

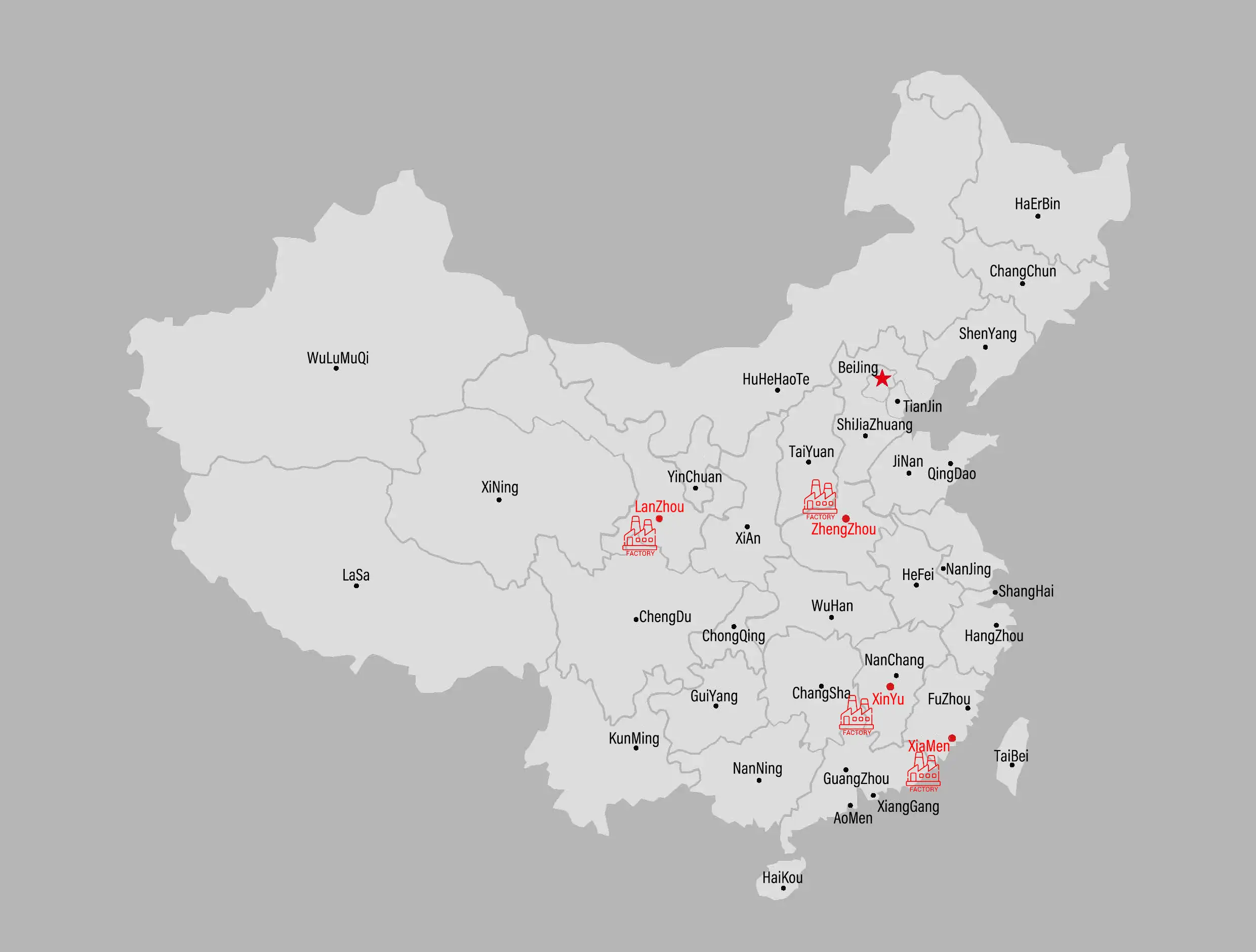

As a key enterprise in Henan Province, Zhengzhou CHYCARBON New Materials was established in 2014, specializing in the R&D and production of casting materials, refractory materials, and metallurgical auxiliary materials. Leveraging the strength of its “Yulida” brand, the company has developed a diversified product line including carburizers, slag removers, and ferrosilicon, widely used in steel smelting and casting processes. Recently, the company attracted strategic investment to optimize its equity structure, further enhancing its technological R&D and market expansion capabilities.

At the summit, CHYCARBON highlighted its self-developed graphitized carburizers and calcined coal carburizer series, featuring low sulfur and high carbon content to significantly improve steel liquid purity, thereby assisting downstream enterprises in reducing costs and boosting efficiency. A company representative stated, “We aim to establish closer partnerships with upstream and downstream enterprises through this summit platform to jointly explore innovative pathways for green metallurgical materials.”

Deepening Supply-Demand Connectivity, Pursuing High-Quality Industry Development

During the summit, organizers held multiple technical exchanges and supply-demand matchmaking sessions to facilitate precise alignment between steel enterprises and furnace material suppliers. Sun Qing, an expert from the China Carbon Association, emphasized the necessity of technological upgrades and resource integration to address market volatility. Professor Zhou Xiangyang from Central South University proposed a “full-industry-chain collaboration” strategy for cost control in anode materials. Meanwhile, institutions such as Shanggang Research Institute and Ansteel Research Institute shared advanced technologies like ultra-clean steel production and steel slag recycling, offering innovative solutions for green industry transformation.

Looking Ahead, Building a New Industrial Ecosystem

As the steel industry transitions toward high-quality development, supply-demand summits have become increasingly vital bridges for industrial chain collaboration. A CHYCARBON official noted that the company will continue to invest in R&D, optimize product structures, and deliver customized solutions aligned with “green and efficient” principles to advance the metallurgical materials industry.

The successful conclusion of this summit not only provided a direct dialogue platform for enterprises but also set clear directions for the industry through technical exchanges and trend analysis. Going forward, all stakeholders will deepen cooperation to collectively drive the sustainable development of steel casting and metallurgical materials manufacturing.