Zhengzhou ChangHeYue New Material CO.,LTd

Graphite Petroleum Coke Usage: Powering Industries with High-Performance Carbon

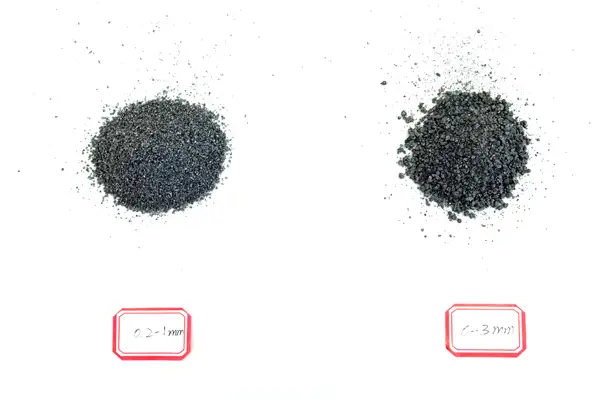

Graphite petroleum coke (GPC) is a premium carbon material derived from oil refinery coking processes. With its ultra-high carbon content (over 98%) and low impurity levels, GPC has become indispensable across multiple industries. This article explores the critical graphite petroleum coke usage scenarios and why it’s a game-changer for sustainable manufacturing.

What is Graphite Petroleum Coke?

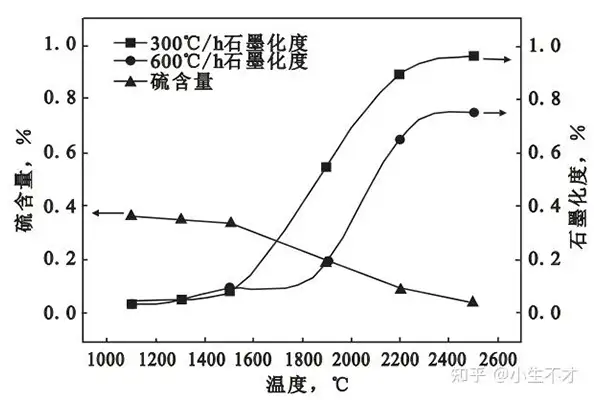

Graphite petroleum coke is a purified form of calcined petroleum coke, processed at temperatures above 2,800°C to achieve crystallized graphite structures. Its unique properties—high thermal stability, electrical conductivity, and carbon purity—make it ideal for demanding industrial applications.

Top 5 Industrial Applications of Graphite Petroleum Coke

1. Aluminum Smelting: The Backbone of Efficiency

graphite petroleum coke in aluminum smelting

GPC serves as the primary anode material in aluminum electrolysis. Its low resistivity reduces energy consumption by up to 20% compared to traditional alternatives, directly lowering production costs for smelters.

2. Steel & Titanium Manufacturing

GPC for steel alloy production

In electric arc furnaces (EAFs), graphite petroleum coke acts as both a carbon raiser and slag foaming agent, improving heat transfer efficiency and extending furnace lifespan.

3. Lithium-Ion Battery Anodes

synthetic graphite from petroleum coke

With the EV revolution, battery-grade GPC is critical for producing synthetic graphite anodes. Its uniform crystal structure enables faster charging and longer battery life.

4. Carbon Brushes & Electrical Components

conductive graphite petroleum coke

GPC’s electrical conductivity (5.0×10⁵ S/m) makes it perfect for brushes in motors and generators, ensuring reliable performance in aerospace and automotive systems.

5. Refractory Materials

high-temperature graphite coke

GPC-enhanced refractory linings in blast furnaces withstand temperatures exceeding 1,600°C, reducing maintenance downtime by 30-40%.

Why Choose Graphite Petroleum Coke?

- 98.5%+ Fixed Carbon Content – Maximizes energy output

- 0.05% Sulfur – Meets strict environmental regulations

- Cost Savings – Reduces anode consumption by 15% in aluminum plants

- Sustainability – 100% recyclable in closed-loop production systems

FAQs: Graphite Petroleum Coke Usage

Q: How does GPC compare to coal-based alternatives?

A: GPC offers 3x higher thermal conductivity and 50% lower ash content versus coal tar pitch.

Q: What’s the global market trend for GPC?

A: The GPC market is projected to grow at 6.2% CAGR through 2030, driven by EV battery demand (Grand View Research).

Optimize Your Operations with Premium Graphite Petroleum Coke

From energy-intensive metallurgy to cutting-edge battery tech, understanding graphite petroleum coke usage unlocks competitive advantages. Partner with certified GPC suppliers to ensure material consistency and compliance with ISO 9001/14001 standards.

Contact us today to request a free sample of high-purity graphite petroleum coke tailored to your industry needs.