Zhengzhou ChangHeYue New Material CO.,LTd

A Comprehensive Guide

1. Understanding Graphitized Petroleum Coke HS Code Classification

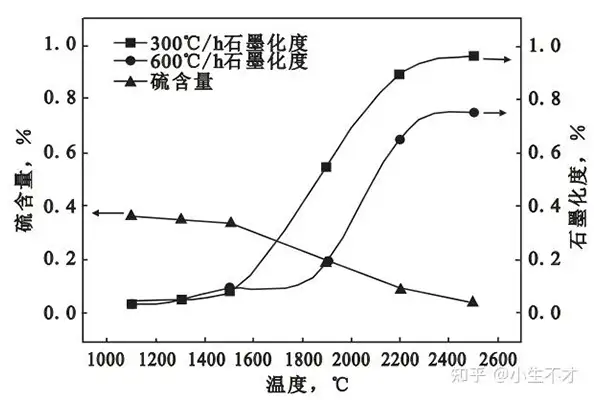

Graphitized Petroleum Coke (GPC) is classified under HS code 3801 when produced via high-temperature graphitization (≥2500°C), distinguishing it from non-graphitized petroleum coke (HS 2713) and amorphous carbon (HS 2803). The classification hinges on crystallinity and production processes:

- HS 3801 (Artificial Graphite): Applies to GPC with near-graphite crystal structures, achieved through electric furnace heating at 2500–3000°C. This aligns with customs guidelines where high-temperature processing defines “artificial graphite”.

- HS 2713 (Petroleum Coke): Covers calcined coke processed below 2000°C, typically used as fuel or electrode raw material.

- HS 2803 (Carbon): May apply if GPC’s production deviates from standard graphite manufacturing methods.

2. Key Applications Driving Global Demand

GPC’s ultra-low sulfur (≤0.05%) and high carbon content (≥98.5%) make it indispensable in:

- Steelmaking: Enhances alloy quality by reducing iron-carbide formation and improving absorption rates.

- Solar-Grade Polysilicon: Critical for high-purity silicon production in renewable energy sectors.

- Foundry Casting: Ensures superior graphite crystallization in automotive and machinery parts.

3. HS Code Disputes and Trade Implications

Misclassification risks tariffs, customs delays, and legal challenges. For example:

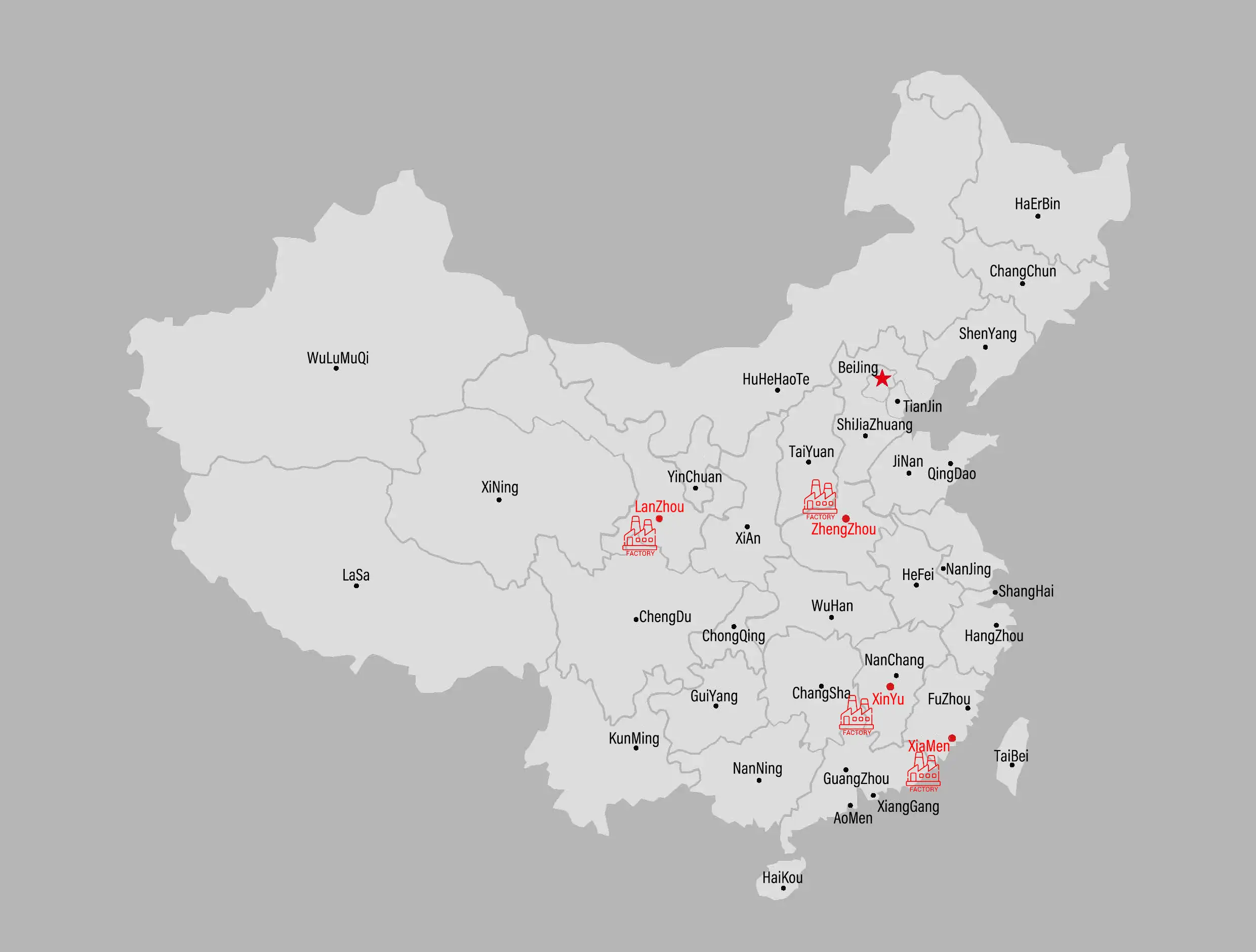

- China’s Dominance: As the top GPC exporter, China faces scrutiny over HS 3801 declarations due to overlapping standards (e.g., GB/T 8718-2008).

- Compliance Strategies: Align documentation with production details (e.g., furnace temperature logs) to justify HS 3801 claims.

4. Technical Specifications for Buyers

Include critical GPC parameters to attract B2B clients:

- Fixed Carbon: ≥98.5%

- Sulfur Content: ≤0.05%

- Ash Content: ≤0.8%

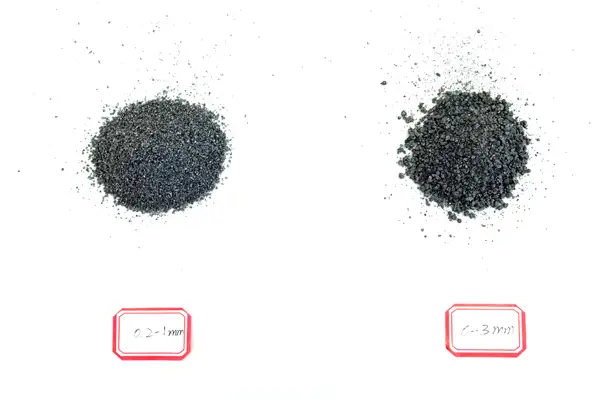

- Particle Sizes: 0.2–10mm (customizable for industrial furnaces).