Zhengzhou ChangHeYue New Material CO.,LTd

1. Overview

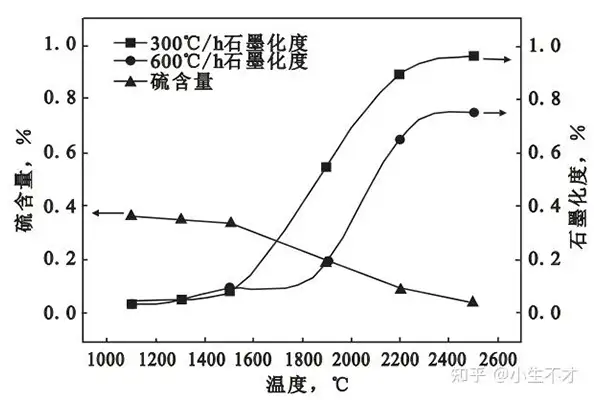

Graphitized petroleum coke (GPC) is a high-purity carbon material produced by heat-treating petroleum coke at extreme temperatures (2,500–3,000°C) to convert amorphous carbon into crystalline graphite. It is widely used in lithium-ion battery anodes, electrodes, and high-temperature applications.

2. Early Processes

Key Steps (Acheson Process)

- Raw Material Preparation:

- Feedstock: High-sulfur petroleum coke from delayed coking.

- Calcination: Heated to 1,200–1,400°C in rotary or shaft kilns to remove volatiles and moisture.

- Graphitization Furnace:

- Acheson Furnace: Batch-type resistance-heated furnace with coke bed as resistor.

- Process:

- Layered coke mixed with graphitization agent (e.g., quartz sand) placed in furnace.

- Electric current (5,000–10,000 A) applied for 20–50 hours.

- Temperature: ~2,800°C.

- Cooling & Post-Treatment:

- Slow cooling over days to prevent cracking.

- Crushing, milling, and purification (acid washing).

Technical Challenges

- High energy consumption (6,000–8,000 kWh/ton).

- Inhomogeneous temperature distribution.

- Long cycle time (5–7 days per batch).

- Poor yield due to oxidation and impurities.

3. Modern Advanced Processes

Key Innovations

- Longitudinal Graphitization (LWG) Technology:

- Continuous vertical furnace with controlled atmosphere (argon/nitrogen).

- Advantages:

- Faster heating/cooling (cycle time: 24–48 hours).

- Energy savings (~3,500 kWh/ton).

- Higher purity (ash content <0.1%).

- Induction Heating:

- Electromagnetic induction furnaces for precise temperature control.

- Reduced thermal stress and improved crystallinity.

- Continuous Graphitization Reactors:

- Rotary tube furnaces with automated feeding.

- Real-time monitoring via AI and IoT sensors.

Equipment

- Modern Furnaces:

- LWG furnaces (e.g., Siemens-style).

- Induction graphitization furnaces.

- Tunnel kilns with inert gas protection.

- Auxiliary Systems:

- Gas purification units (HCl/Cl₂ removal).

- High-efficiency dust collectors.

4. Technical Parameters

| Parameter | Traditional (Acheson) | Modern (LWG) |

|---|---|---|

| Temperature | 2,800–3,000°C | 2,800–3,000°C |

| Graphitization Time | 50–70 hours | 20–30 hours |

| Energy Consumption | 6,000–8,000 kWh/ton | 3,000–4,000 kWh/ton |

| Carbon Yield | 70–80% | 85–95% |

| Resistivity | 8–12 μΩ·m | 5–7 μΩ·m |

| CTE* (×10⁻⁶/°C) | 2.5–3.5 | 1.5–2.5 |

CTE: Coefficient of Thermal Expansion

5. Key Challenges & Solutions

- Temperature Uniformity:

- Issue: Hotspots/cold zones in traditional furnaces.

- Solution: Multi-zone induction heating + AI-based thermal management.

- Energy Efficiency:

- Solution: Waste heat recovery systems (e.g., preheating feedstock).

- Oxidation & Contamination:

- Solution: Inert gas shielding (N₂/Ar) and vacuum furnaces.

- Feedstock Quality:

- Requirement: Low sulfur (<0.5%) and metals (Ni, V <50 ppm).

- Innovation: Advanced calcination with catalytic additives.

6. Operational Steps (Modern Process)

- Feedstock Preparation:

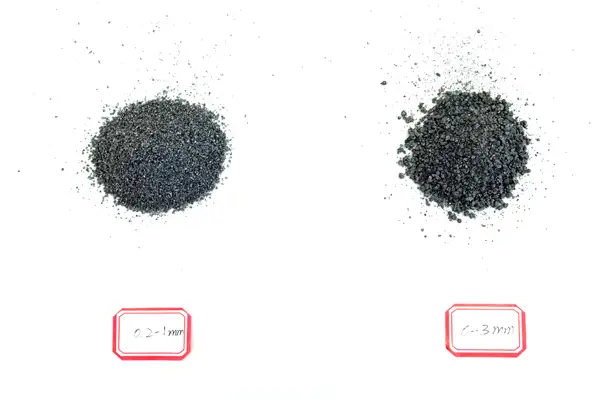

- Crude coke → Calcination (1,400°C) → Pulverizing (D50: 10–20 μm).

- Furnace Loading:

- Automated feeding into LWG furnace with graphite crucibles.

- Graphitization:

- Ramp-up to 2,800°C at 100°C/hour; hold for 10–15 hours.

- Cooling & Extraction:

- Controlled cooling under inert gas (50°C/hour).

- Post-Processing:

- Milling, sieving, and surface coating (pitch/chemical vapor deposition).

7. Future Trends

- Microwave Graphitization: Ultra-fast heating (<1 hour) with targeted energy.

- Sustainable Processes: Hydrogen as reducing agent to cut CO₂ emissions.

- Nano-Structured GPC: Enhanced electrochemical performance for batteries.

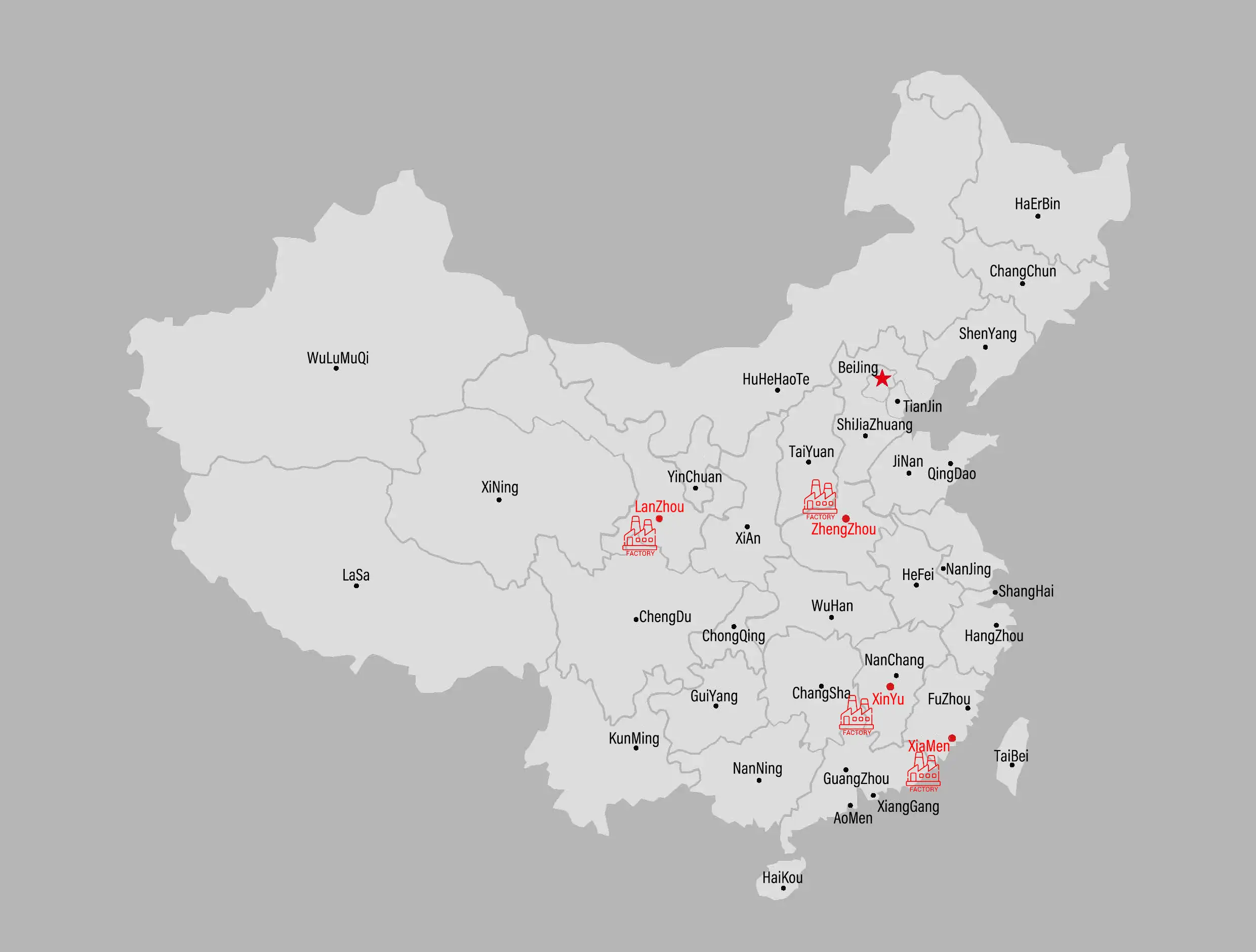

8. CHYCARBON: Pioneering the Future of Graphitized Petroleum Coke

At CHYCARBON, we are not just manufacturers of graphitized petroleum coke – we are innovators, engineers, and visionaries committed to redefining the boundaries of advanced carbon materials. With decades of expertise and a relentless pursuit of excellence, we have positioned ourselves as a global leader in high-performance GPC production, powering industries from lithium-ion batteries to aerospace.

Our Commitment to Innovation

- Cutting-Edge Technology: We are trusted by Fortune 500 companies to provide customized solutions to steel companies and the world’s leading foundries, driving the transition to a green economy.

- Breakthrough Capacity: By integrating continuous graphitization reactors and automated systems, we have scaled production to meet surging global demand, delivering 150,000+ tons annually with precision and reliability.

- Sustainable Solutions: Pioneering eco-friendly practices, including waste heat recovery and hydrogen-based reduction, we reduce carbon footprints while maintaining ultra-low impurity levels (ash <0.1%, sulfur <0.03%).

Our Vision

At CHYCARBON, we believe that the future of carbon lies in smarter, cleaner, and more efficient technologies. By continuously challenging the status quo, we aim to:

- Double Production Capacity by 2030 through modular furnace expansions.

- Achieve Zero-Waste Operations via closed-loop recycling systems.

- Empower Global Decarbonization with GPC that enables longer-lasting batteries and cleaner industrial processes.

Join us in shaping a carbon-powered future – where innovation meets responsibility.