Zhengzhou ChangHeYue New Material CO.,LTd

Introduction to Sulfur in Petroleum Coke

Petroleum coke (petcoke), a critical raw material in carbon product manufacturing, is categorized by sulfur content into low-sulfur (<2%), mid-sulfur (2–4%), and high-sulfur (>4%) grades. Traditionally, low-sulfur coke dominated carbon production due to its stability. However, dwindling low-sulfur coke supplies have forced industries to adopt mid- and high-sulfur alternatives. This shift introduces challenges: sulfur volatilization during high-temperature calcination (above 1,500°C) significantly impacts coke’s microstructure, graphitization efficiency, and final product quality.

Key challenges include:

- Crystal expansion: Inorganic sulfur release above 2,400°C induces microcracks in graphite products.

- Density limitations: Sulfur content >4% reduces true density of calcined coke.

- Resistivity risks: Excessive sulfur increases porosity and electrical resistivity.

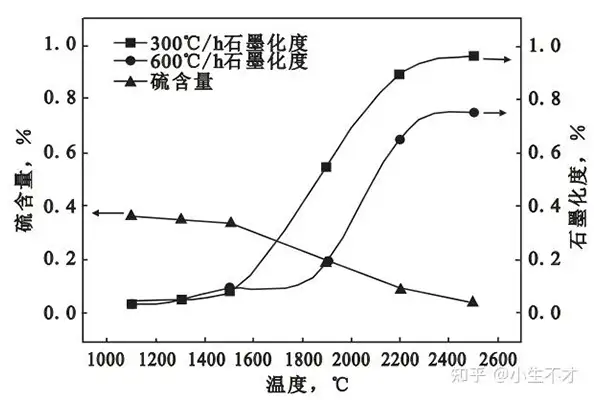

Sulfur Release Dynamics and Graphitization

Temperature-Dependent Sulfur Volatilization

- Below 1,500°C: Minimal sulfur release and no graphitization.

- 1,500–2,200°C: Rapid sulfur volatilization triggers structural transformation:

- Pore development accelerates.

- Crystallite layer spacing decreases (d002).

- Graphitization degree surges due to sulfur’s catalytic gasification.

- Above 2,200°C: Sulfur release slows, graphitization plateaus. Residual sulfur drops to trace levels at 2,500°C.

Critical Insight: Optimizing sulfur’s thermodynamic release kinetics (e.g., controlled heating rates) can accelerate graphitization without inducing structural defects.

Impact of Sulfur Release on True Density

Experimental data reveals a direct correlation between sulfur volatilization and true density:

- <1,500°C: Slow sulfur release → density increases marginally (0.05–0.10 g/cm³).

- >1,500°C: Accelerated sulfur escape → density rises sharply (up to 0.30 g/cm³).

Mechanism: Sulfur removal reduces pore-forming impurities, densifying the coke matrix. High-sulfur coke (>4%) requires precise temperature control to balance density gains and crack risks.

Optimizing Graphitization: Strategies for High-Sulfur Coke

- Controlled Heating Rates

Avoid excessive ramp-up speeds (>50°C/min) to prevent uneven sulfur release and microcracking. - Multi-Stage Calcination

- Stage 1: 800–1,200°C (organic sulfur removal).

- Stage 2: 1,500–2,200°C (inorganic sulfur release + graphitization).

- Stage 3: 2,300–2,500°C (final densification).

- Additive Catalysts

Iron or boron compounds can lower sulfur’s activation energy, enabling efficient removal at lower temperatures. - Post-Calcination Treatments

Mechanical compression or chemical vapor infiltration (CVI) to mitigate porosity.

Conclusion

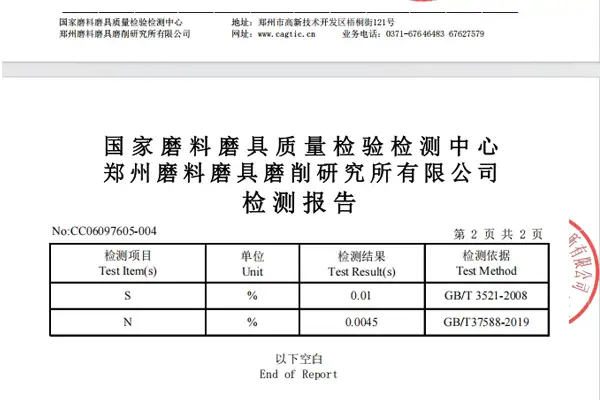

High-temperature sulfur release profoundly shapes petroleum coke’s graphitization efficiency and product quality. Key takeaways:

- Sulfur volatilization above 1,500°C drives graphitization but requires kinetic control.

- True density improvements correlate with sulfur removal rates.

- Strategic thermal profiling and catalytic additives minimize defects in high-sulfur coke processing.

For industries adopting mid/high-sulfur coke, optimizing calcination parameters is essential to balance cost, performance, and sustainability.