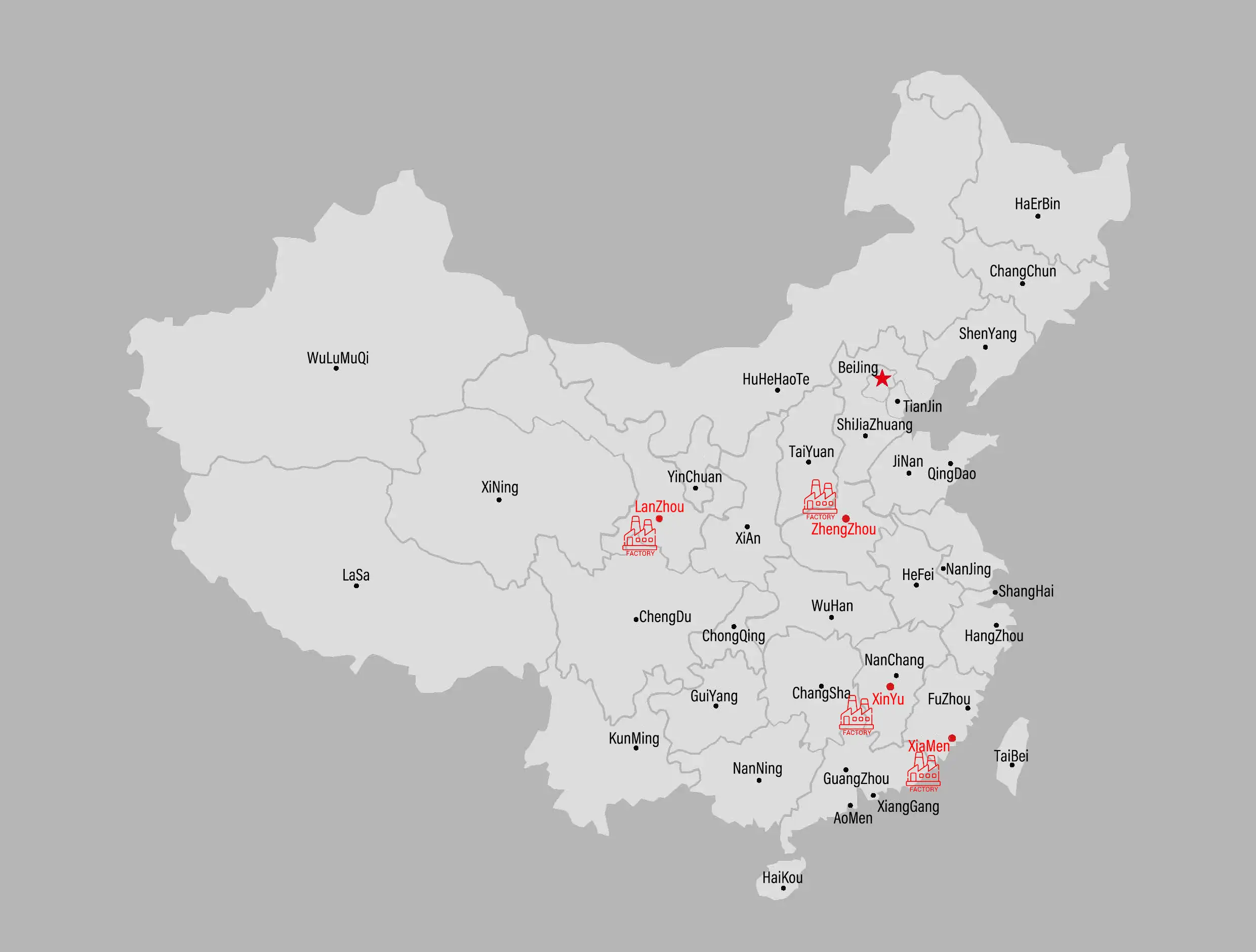

Zhengzhou ChangHeYue New Material CO.,LTd

Analysis of Graphitized Petroleum Coke (GPC) Market Price Fluctuations in February 2025

I. Core Characteristics of Price Fluctuations

- China Market: The price is expected to range between 5,800-7,500 RMB/ton (approximately 800-1,030 USD/ton). High-end products (sulfur content <0.5%) will be supported by lithium battery demand, while low-end products (sulfur content >2.0%) may drop to 4,500 RMB/ton due to overcapacity.

- International Market Prices:

- North America: 900-1,200 USD/ton (reliant on imported high-end products with insufficient local supply);

- Europe: 1,000-1,300 USD/ton (driven by carbon tariffs and green supply chain costs);

- Southeast Asia: 850-1,100 USD/ton (driven by Chinese capacity relocation and regional expansion of the new energy industry chain).

- Drivers of Fluctuations

- Seasonal Fluctuations: February 2025 coincides with the Chinese Spring Festival holiday. Pre-holiday stockpiling by anode material companies may cause a short-term price surge in late January to early February, followed by a slight decline after the holiday due to logistics resumption and inventory release.

- Extreme Weather Risks: Winter in the Northern Hemisphere may impact raw coke transportation and GPC plant operations (e.g., North American cold waves, power restrictions in Northern China), exacerbating supply shortages.

II. Evolution of Supply-Demand Dynamics

- Supply Side

- Concentrated Capacity Release in China: Approximately 800,000 tons/year of new graphitization capacity will be added in Northwest China (Inner Mongolia, Xinjiang) during 2024-2025. Low-cost electricity (below 0.3 RMB/kWh) will drive down processing fees, but high-end product capacity will remain structurally insufficient.

- Restructuring of International Supply Chains:

- India and Vietnam will build their own graphitization capacities (totaling approximately 300,000 tons/year by 2025), reducing reliance on China;

- Russia will capture Eastern European markets with low-priced raw coke (higher sulfur content), depressing regional low-end product prices.

- Demand Side

- Dominance of New Energy Demand: Global power battery capacity is expected to exceed 3TWh by 2025, with anode material demand growing at 25% annually, supporting high-purity GPC prices;

- Weak Recovery in Traditional Industries: The aluminum electrolysis industry will benefit from lightweight trends (automotive, aerospace), but slow ramp-up of green aluminum capacity in Europe will limit growth in ordinary GPC demand to 3-5%.

III. In-Depth Analysis of Key Influencing Factors

- Policy and Carbon Barrier Upgrades

- Full Implementation of EU CBAM: The mandatory phase of the carbon tariff in 2026 will compel European importers to prioritize low-carbon footprint GPC (benefiting green power capacities in Western China), potentially creating a premium of 15-20%.

- Optimization of China’s “Dual Control” Energy Policy: Under the green power quota system, high-energy-consuming graphitization capacities in Southeast China will be phased out, further widening regional price gaps.

- Technological Substitution Risks

- Accelerated commercialization of silicon-based anodes (potentially reaching 10% penetration by 2025) may partially replace high-end artificial graphite demand, capping GPC price ceilings;

- Breakthroughs in direct graphitization of raw coke (reducing costs by ~30%) could disrupt traditional pricing systems if scaled.

- Geopolitics and Trade Frictions

- U.S.-China Critical Minerals Rivalry: If GPC is included in the “sensitive materials list,” Chinese exports to the U.S. may face additional tariffs;

- Prolonged Red Sea Shipping Crisis: Rising Suez Canal transit costs will push up European landed prices.

IV. Regional Market Fluctuation Forecasts

- China Market

- “Spring Festival Effect”: Pre-holiday stockpiling may push prices up to 7,000 RMB/ton in January, followed by a decline to 6,300-6,500 RMB/ton in late February due to anode manufacturers destocking.

- West vs. East Price Gap: GPC prices in Inner Mongolia will be approximately 1,200 RMB/ton lower than in Shandong, attracting procurement by battery manufacturers in South China.

- European Market

- Local zero-carbon steel projects (e.g., HYBRIT) will increase demand for low-carbon GPC, potentially pushing Nordic landed prices above 1,300 USD/ton in February;

- Low-priced Russian resources (800-900 USD/ton) will enter through Belarus, impacting markets in Poland and Germany.

- North American Market

- The Biden administration’s Inflation Reduction Act subsidies for the local lithium battery industry chain will stimulate GPC imports, increasing by 20% year-on-year. However, port strike risks may heighten spot price volatility in February.

V. Risk Warnings and Strategic Recommendations

- Price Fluctuation Risks

- Upside Risks: Extreme weather, Red Sea shipping disruptions, slower-than-expected silicon-based anode mass production;

- Downside Risks: Slower-than-expected growth in global lithium battery demand, breakthroughs in raw coke graphitization technology.

- Corporate Strategy Recommendations

- Lock in Long-Term Contracts: Leading lithium battery companies can sign 3-year fixed-price agreements with Northwest Chinese suppliers to hedge cost risks;

- Diversify Procurement: European importers should establish a multi-channel supply system (China + Russia + India) to avoid geopolitical premiums;

- Invest in R&D: Accelerate the development of direct graphitization technology to reduce reliance on traditional calcination processes.

VI. Conclusion

The GPC market in February 2025 will exhibit “high volatility and strong differentiation,” with prices influenced by new energy stockpiling, policy incentives, and black swan events. High-end products will maintain price resilience, while low-end products will face increasing pressure from capacity clearance. Market participants are advised to focus on:

- Arbitrage opportunities arising from capacity release in Northwest China and cost inversion in the East;

- Green certification demands triggered by EU carbon tariffs;

- Long-term impacts of anode material technology shifts on GPC demand.

Data Sources: BloombergNEF, CRU Group, China Petroleum and Chemical Industry Federation, industry expert interviews.

Note: This analysis is based on current trends and may deviate from actual prices due to unforeseen events.